Pneumatic Actuators

Applications: Part turn actuators are used for the automation of valves, which are controlling the flow of different medias (fluid, gas) or granulated material.

All actuators of the Edition 2010 line (4th Generation Upgrade) are service friendly by external travel stops for open and close position adjustable from -5° to +15° and from +75° to +95°. This special feature eliminates alignment problems due to a clearance of connections between the stem of the valve adaptor and the shaft of the actuator.

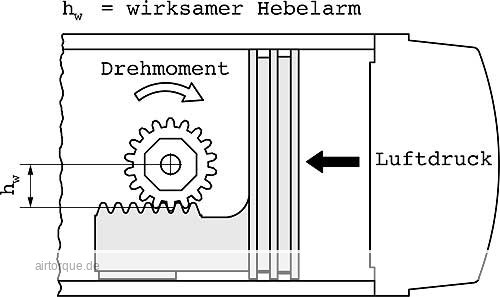

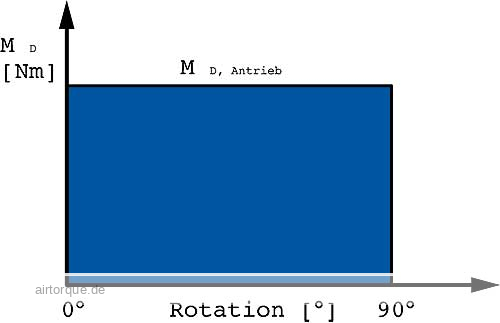

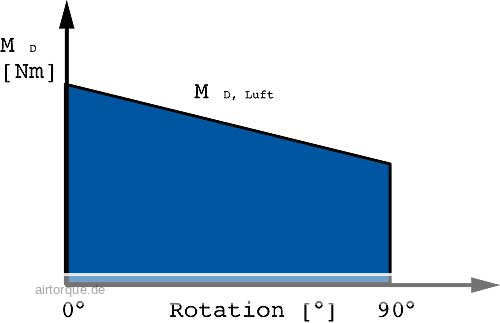

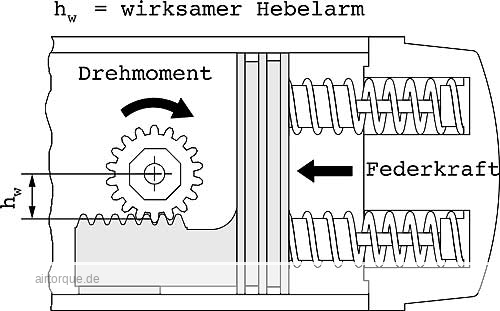

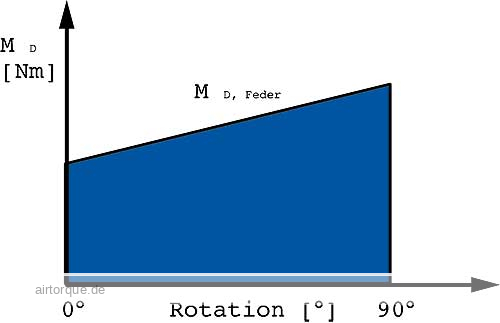

Due to a triple bearing of the piston all actuators have a constant torque, even under high load. Beside the guides on the outside of the piston there is an additional guide inside which absorbs the cross load through the integrated support at the drive shaft.The drive shaft is held in position by two bearings, one at the top of the pinion, one at the bottom. This assures less friction and abrasion-free operation.

Due to the special design of the bearings at the shoulders of the piston, the drive shaft is blowout proof and fulfills the hard US-standards for product liability.

The drive shaft has a 25-30 µm electroless nickel coating (Protection E -> Stainless steel).The bearings are temperature resistant to 155 °C. Due to an internal retaining shoulder the bearings are blowout safe.

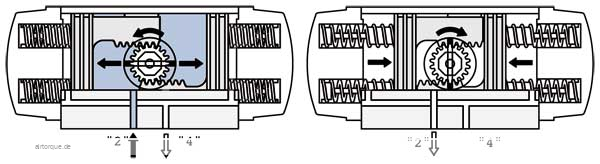

The maintainance free spring cartridges allow a safe and simple assembly and disassembly. Therefore the adaptation of the AT actuators to your working conditions with the recommended pneumatic pressure can be arranged easily. The modification of a double acting to a spring return actuator can be easily managed. Only the necessary springs have to be mounted. This advantage of AT actuators reduces stocking costs significantly.

Silicon free:

All actuators are silicon free.

Serial inspection:

Each actuator has to pass a comprehensive serial inspection with e.g. a tightness / density check and a torque check.

After passing the inspection the actuator is given a serial number according to ISO 9001.

Quality Assurance:

The company received the highest international ISO 9001 certification by Lloyd’s Register of Shipment.